Production & Tech

Carbon engineering is the science of manipulating carbon material to optimize the desired design and performance features of a given product. These outcomes can be achieved with steps as practical as innovating or sourcing better material, or as involved as reimagining the whole manufacturing process with new molds and layup methods.

Basic carbon products can be impressively elevated and improved with skilled carbon engineering, and this is what we strive for at Light Bicycle. Let’s delve into a more detailed understanding of our core engineering practices and achievements, as well as the full process of taking a new design from concept to a premium, functional carbon product.

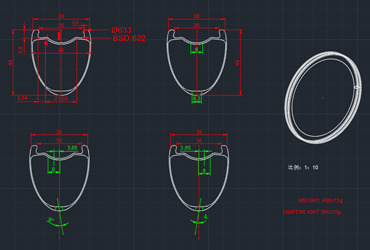

This starts with our engineering team receiving a new project from an OEM or ODM client. If the product is still in the early ideation stage, the engineers refine the specifics of the design and create a product drawing with CAD software. A product design may go through multiple iterations to arrive at the best design to fulfill the client’s requirements.

To optimize the design, we perform further analysis by using the Finite Element Method (FEM) to simulate how the product will behave under different external conditions. For rims in particular we simulate strong winds, heavy loads, and wheel building with hubs and spokes to confirm compatibility with industry-standard components. This practice eliminates unnecessary development loops. With all the details confirmed, a 3D prototype is printed and sent to the client for review. The simulation results are later reviewed and validated in our test lab.

Lay-up is the process of overlaying carbon prepregs in a specific order and orientation to achieve the desired stiffness and strength. The engineers create an accurate layup plan for the manufacturing technicians to follow according to the customer's needs. If an innovation is necessary for the desired attribute we develop and introduce it in a way that keeps production efficiency as high as possible.

Using the CAD product drawing as reference, the engineers design the production molds and collaborate with the mold manufacturer to achieve the desired precision and durability. Typically a mold construction takes into account universality, convenience of use for technicians, and the ease of product removal and mold maintenance.

We are continually testing new ideas and furthering the pursuit of lighter, stronger, and more aesthetically striking products manufactured as sustainably as possible. These are a few of our most innovative engineering achievements.

X-Flow Profile

S-Flow Profile

Dual-ERD™

Asymmetric Rim Profile

Grooved Graphene Brake Track

Tubeless Compatibility

Single-Wall Structure

Stepwise Cross-Link Lay-up

Laminate Orientation

Sizing Accuracy

Customized Epoxy Resin

No Carbon Curing Ring

No Rim Bed Patching

Smooth Wall Technology

Flyweight Construction Method

BlackTek

Environmentally-Friendly Release Agent

Webform

Name / Email / Company / Business Type / Request Type

Global office

+86-0592-6254228/+86-18030305013

08:30-17:45 (BJT)

Get QR code & chat!